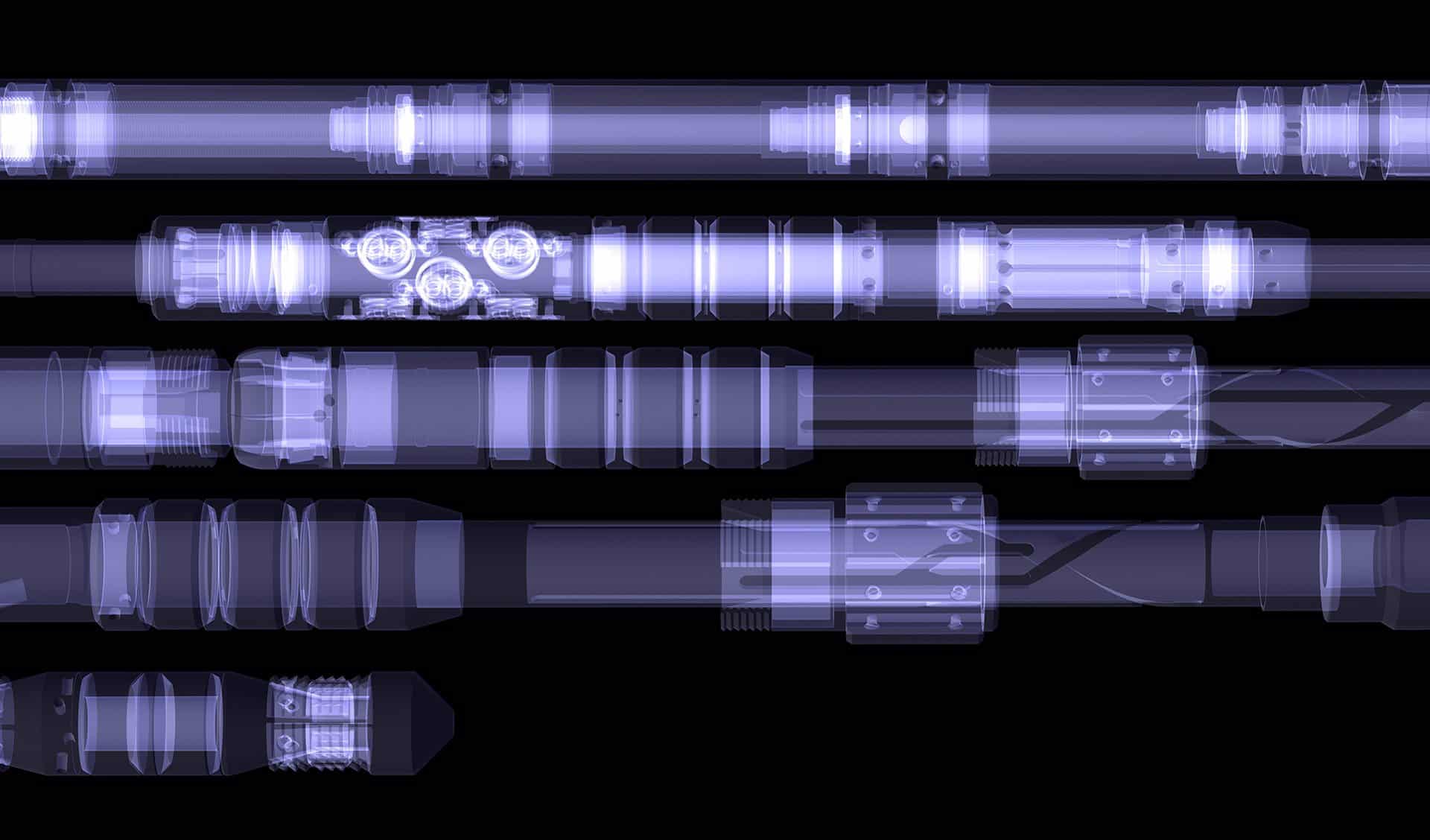

Phased Array Ultrasonic Testing (PAUT)

Phased Array Ultrasonic Testing is the advanced method of conventional Ultrasonic Testing making the detection, location and characterization of defects more reliable and exact.

PAUT Advantages

- Faster scanning speeds compared to Ultrasonic Testing

- Multiview display provides easier flaw characterization

- Improved detection of discontinuities compared to Ultrasonic Testing

- Wide area coverage for full corrosion mapping, thickness monitoring and recording

- More advanced welding inspection for defects

- Data can digitally be saved and stored for future review

Shear Wave Detection

Angle-beam testing, also referred to as shear wave, is a widespread method used to identify imperfections and examine newly constructed welds, structural steel welds, and in-service welds. This testing method uses sound waves that are generated at a specific angle to the weld to determine the presence of defects such as cracks or discontinuities.

Advantages of Shear Wave

- Safe and eco-friendly design to ensure minimal harm to personnel and the environment

- Real-time reporting to quickly provide results

- Accurate detection and characterization of flaws, as well as precise sizing and locating of defects

- Single-side accessibility for efficient inspections

- Portability for convenient on-site use

- Mobility for ease of transportation

Reliable,

Credible,

Proven Experts

For over 20 years, our expert technicians have provided high-quality Non-Destructive Testing (NDT) to the country’s leading oil and gas companies. Available 24/7, our crew is trained to use our state-of-the-art equipment and the latest technology to minimize your team’s downtime and maximize productivity.