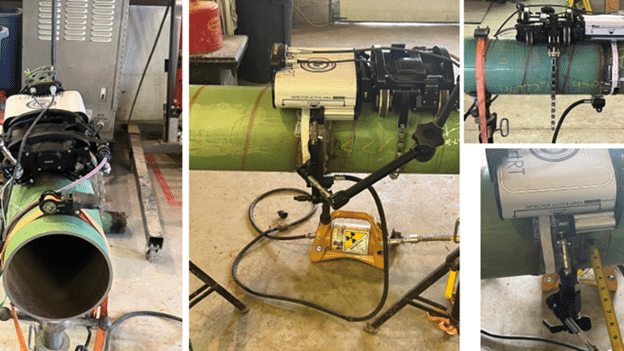

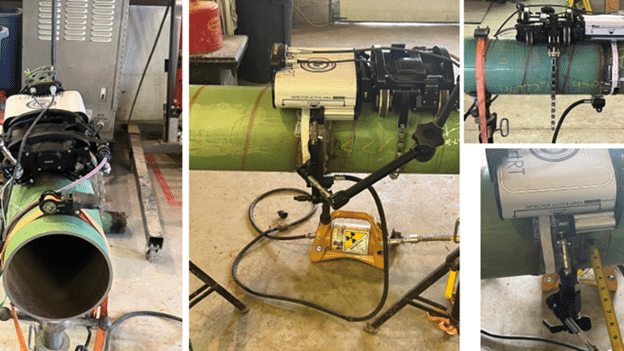

Computed Radiography

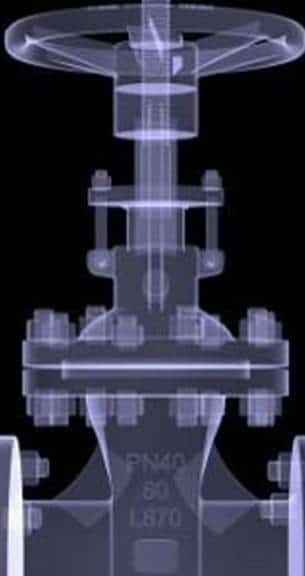

Computed Radiography utilizes computed digital imagery that allows for a sharper more enhanced image for better evaluation. CR inspection is a safer, timelier, and more detail-oriented inspection overall.

Advantages of Computed Radiography

- Safer than traditional x-ray/gamma ray methods

- Faster exposure times

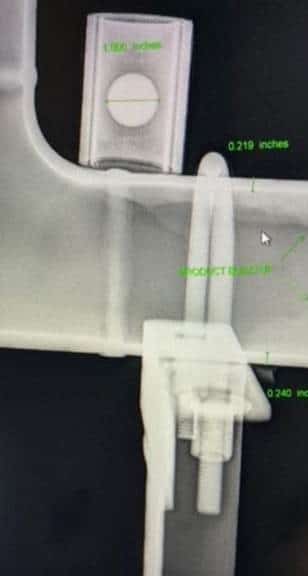

- Improved images for flaw evaluation

- Better archiving and storage

- Increase productivity any many cases

- Quick processing times

- Can be used in leu of conventional X-Ray on all pipe sizes

- Used for wall loss and product build up

- Digital flaw sizer

Digital Radiography

Advantages of Digital Radiography

- Significantly reduced total inspection time vs. CR and conventional methods on 3” to 12” pipe

- Minimized or eliminated re-shots

- Fine grain/slow speed film equivalent image quality.

- Improved safety and production with one crank out- one crank in per weld

- Auto generation of scan plans for various pipe configurations

- System can be easily adapted to perform manual small diameter DWE/DWV applications

- Digital flaw sizer

Reliable,

Credible,

Proven Experts

For over 20 years, our expert technicians have provided high-quality Non-Destructive Testing (NDT) to the country’s leading oil and gas companies. Available 24/7, our crew is trained to use our state-of-the-art equipment and the latest technology to minimize your team’s downtime and maximize productivity.